Published: 14 November 2025

Infrastructure monitoring projects run on decisions, and decisions rely on data that is clear, timely, and trusted. By its very nature, Structural health monitoring is supposed to be that simple: measure the right parameters, detect change early and respond in time.

On paper, the path looks straightforward.

In practice it slows at each handoff. Be it from sensor to datalogger, from connectivity to platform and from dashboards to decision intelligence. Each step looks small and together they ascertain whether project teams advance or get stuck due to delays.

One night on an important project in Saudi Arabia, an alert appeared on one platform. Two others showed different values for the same minute. The duty engineer waited until the feeds matched before calling action. The delay came from systems speaking in different ways, not from the measurements.

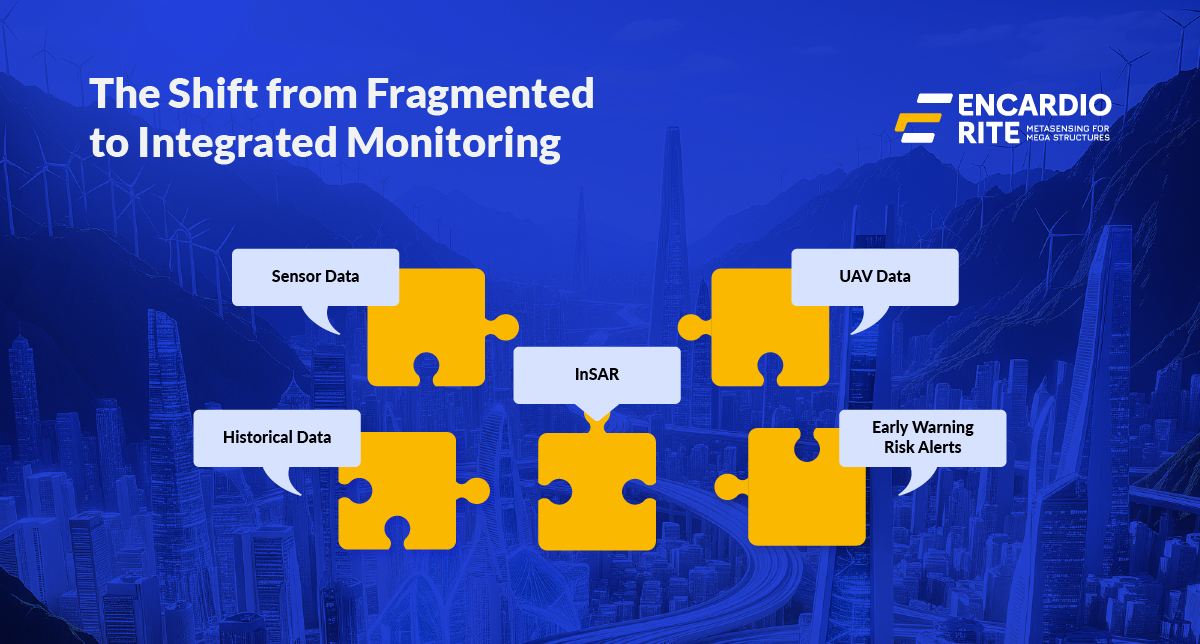

Fragmentation is a common cause. It begins with small choices that look reasonable. Sensors from one supplier, dataloggers from another, separate tools for data, remote sensing, and support. Each sensor arrives with its own connectors, sampling rates, and telemetry protocols. The software stack splits as well. One place for ingestion and processing and another for analysis and reporting. Each uses its own schema, format, its own update cycle.

InSAR, UAV photogrammetry, LiDAR, and total stations often arrive with distinct formats and timestamps. Support threads multiply and ownership blurs. A threshold trips, an alert is missed, and the room asks the question that matters: do we trust this enough to act. Most days, someone opens another support window and checks again.

The issues do not appear at once. First, commissioning begins to stretch longer than expected. Then integration costs quietly start to climb. Soon, small mismatches in versions and schemas slip through, and before anyone realizes, alerts begin to fail or datasets turn corrupt. The reliability that once inspired trust starts to waver, and gradually, the confidence people place in the system begins to fade. When there is a mismatch in data, escalation bounces between vendors. The more players involved, the longer the troubleshooting. Monitoring turns from safeguard to compliance task.

The answer is not more data. The answer is context and correlation. When signals align across time and location, action is justified. When they do not, teams pause and second-guess. Confidence is the overlap in stories told by different instruments observing the same moment. Fragmentation keeps those stories apart.

So, what the industry truly needs is end-to-end integrated monitoring.

It works when one accountable source manages the chain. It starts in the field, where sensors for geotechnical, structural, and environmental parameters feed into standardized dataloggers seamlessly together. Every connector is validated, data formats and schemas are consistent, and communication protocols are aligned. Telemetry, whether cellular, radio, satellite, or wired, is tested as a complete system rather than left to individual vendor handshakes.

Carry the same discipline to the platform. Remote sensing, surveying, and geospatial inputs do not sit off to the side. They arrive on the same platform as ground sensors and are mapped to a unified schema so field names, units, and timestamps match. This removes the late-night task of exporting half a project into spreadsheets just to place pore pressure, displacement, and satellite readings on the same timeline. With integration, correlation is immediate and the signal of change is visible when it matters.

Analytics then closes the loop. A unified dataset enables AI and machine learning to clean noise, correlate parameters, and forecast behavior across subsurface, structural, and spatial domains. Instead of reacting to isolated spikes, engineers see context: a displacement is meaningful only when read against pore pressure and survey coverage. What would once have triggered costly call-out becomes a validated event, or a dismissed false alarm. That difference is the measure of confidence. And confidence begins at commissioning.

In an integrated setup, commissioning is not an ending but a proper start. Sensors connect cleanly. Performance is verified. Alerts are tested with proof in hand from day one. From there, the gains build. Installations become simpler for engineers. Risk falls for contractors. Insights grow stronger for consultants. Asset owners receive decision intelligence they can stand behind.

This is not theoretical. On one of the major projects in Saudi Arabia, the team began with multiple systems operating in separate software environments. MOVE vibrometers with gateways, Nanometric seismographs, IDS GeoRadars, and Encardio instruments, alongside the PROQIO platform, each sat in its own place. Through coordinated work between third-party software teams and the PROQIO development team, data streams were brought into PROQIO using stable API and FTP pull or push processes. All instrument data now lands in one platform. Contractor, designer, and owner have real-time access to the complete dataset. Engineers view, analyze, and correlate readings with site activities without switching between systems. Interpretation is faster. Reporting cycles are cleaner. Decisions are made with less delay. The outcome is a working example of platform interoperability that reduces manual effort and improves visibility for all parties.

There was a time when structural health monitoring was fragmented. Systems worked in silos, responses were slow, and reliability was in doubt. Delays accumulated. Doubts lingered. Resources were wasted. Today the path is clearer. Integrated SHM brings the chain into one consistent flow. Signals move faster. Actions are clearer. Decisions carry evidence.

In infrastructure, timelines are tight, and risks are high. Integration is no longer optional. The next time an alert arrives in the middle of the night, the question is simple. Will your team compare windows, or will they see the same moment together and act.

Categories

Instrumentation

Keywords

geotechnical engineering, Data Collection, Renewable Energy Integration in Infrastructure, Advances in Underground Construction Monitoring, Monitoring, asset safety, End to end monitoring, Integrated monitoring